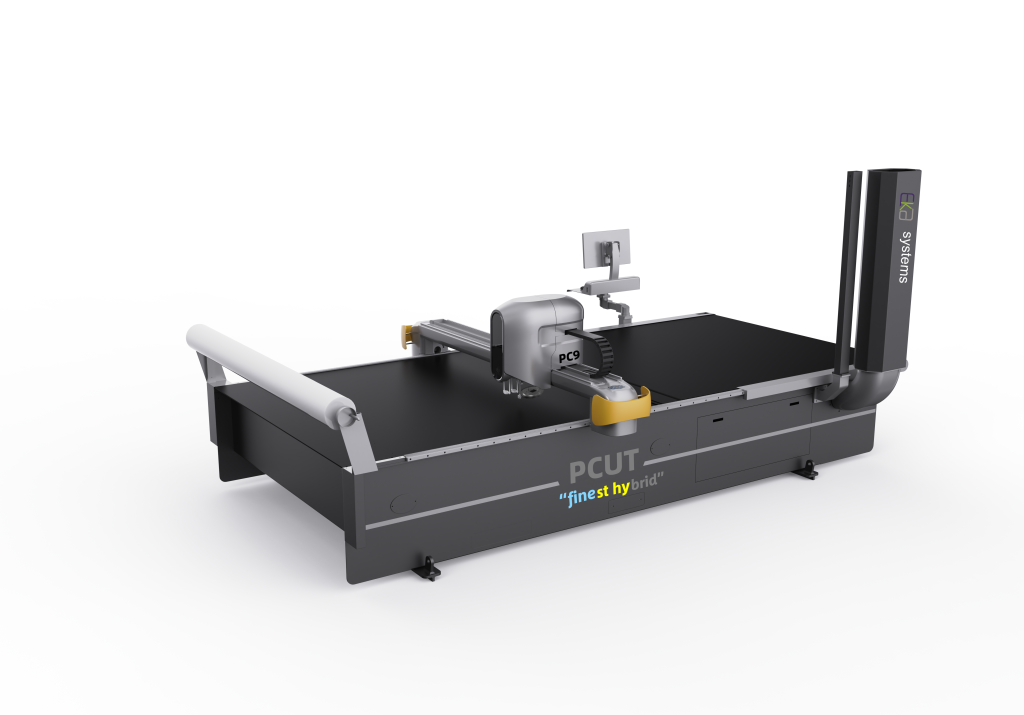

SMART CUTTING ROOM SOLUTIONS

PCUT “Finest hybrid” cutting technology can handle Lays from single up to 90 MM compressed of varies material type. Designed to achieve the highest level of performance, perfection and precision with highest up-time on cutting hours. Smart cut software built in on the machine assures best cutting deliverables and reports in real time with ease of interface to management execution system (ERP).

Technical Specification;

| Model No. | PC 90 |

| Cutting Height (after air draft and compression) | 90 mm |

| Cutting area | 1800*1800/2000/2200 MM |

| Blade size | 2.4*8.5 MM |

| Max Cutting Speed | 120 m/min |

| Max Acceleration | 10 m/s2 |

| Vibration frequency (RPM) | 6500 r/min |

| Average Power Consumption | 10 Kw |

| Max Vacuum negative pressure | -25 kpa |

| Equipment size (L*W) | 4927*2230/2430/2630 mm |

| Machine weight | 3800-4200 kg |

| Workbench Height | 800-900mm |

| Voltage | AC380/50/60 V/hz |

| Power | 28 Kw |

| Air Flow Unit | 160 NL/rin |

| Compressed air pressure | 0.7 Mpa |

| Noise Level | <73 db |

| Cad compatible | Cut file, RS274D |

| Operating system | Windows |

PRODUCT ADVANTAGES

CUTTING WHILE ADVANCING

Compare to other conveyor advancing system, PCUT cutting system can cut material advancing without any operation intervention. This technology can reduce the cutting time, improve the cutting efficiency and optimize your productivity.

WEAR WELL

PCUT cutting machine control software embedded operation schedule, intelligent reminder replacement life expired vulnerable parts, prevent failure and wear of other linkage parts. Continuously ensure cutting quality, efficiency and equipment durability.

Embedded operation problems, you can easily grasp the wear cycle of vulnerable parts, and you can carry out preventive maintenance. Ensure the stability of the equipment and greatly improves its service life.

HIGH-PRECISION

Corrective Smart correction technology can modify the cutting path constantly through the smart stress inside the pressure foot which also can reduce the control deviation in the plies of pieces.

This special technology ensures the tolerance consistency between top pieces and bottom pieces even under a high vibration condition.

The cutting speed can be adjusted intelligently, which improves the traditional semi-automatic cutting does not have the function of intelligent speed matching and ensures the cutting adjustment and edge cutting.

Gas pressure adjustment adopts advanced digital control technology, which can automatically set different pressures according to different fabrics, with accurate traceability.

INTEGRATED MACHINE BED

The High Quality dense arch cast iron integrated bed body is adopted, and all the structural parts adopt finite element analysis. And a series of complex processes such as large gantry milling machine processing, annealing stress removal, to provide affective support for long-term stable cutting while reducing customers, end installation process, shorten the installation delivery cycle.

SAVE FABRIC:

Through the combination of zero-gap cutting technology and machine cutting (walking and cutting), P-Cut cutting machine effectively saves the amount of fabric and greatly reduces the production cost of enterprises.

Embedded operation problems, you can easily grasp the wear cycle of vulnerable parts, and you can carry out preventive maintenance. Ensure the stability of the equipment and greatly improves its service life.

ADEQUATE EQUIPMENT POWER

Through the high-speed motor supporting the industry-leading shock box control technology, effectively improve the number of cutting layers, cutting speed, greatly improve the cutting capacity. The main shock of the cutter can reach 6500 r/min to ensure the power of the equipment 15000 r/min high speed automatic grinding. Different types of stand belt can be used to ensure that the blade remains sharp to easily cope with various fabrics.

ZERO GAP CUTTING

The clearance of the cutting sheet is determined by the free layout of the material discharging software, but the more advanced cutting equipment can realize the cutting of fabric with smaller gaps, or even zero clearance cutting to produce qualified cutting sheet. The study shows that every 1mm reduction of the discharge clearance can save 1% of the fabric. For a better material saving, P-Cut cutting software can realize a litter material with 0 cutting save you more money on your fabrics